| HOME | Schematics | Hobby Corner | Dave's Circuits | Electronic Resources | Book Corner | Contact Info |

|

|

| Back of the Envelope |

|

LED Lighting Economics (February 19, 2010) |

|

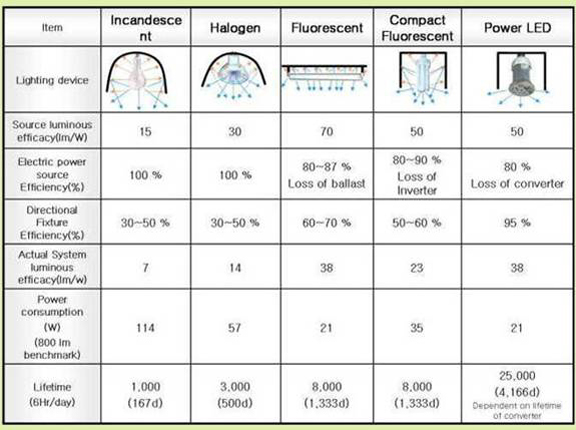

| This is page 2 Although light emitting diodes (LEDs) have been around for at least 3 decades, they are now getting lots of press. The buzz is because, for the first time these devices are producing much more light than other traditional light sources and they use less power. The table below lists the typical electrical power to light conversion factor for various light sources. |

|

When jumping from incandescent

lamps to compact fluorescent lamps, the power savings are huge and easy to calculate.

However, when moving from fluorescent lamps, such as those often used in office buildings,

to LED lighting, the savings are not that clear. The main reason, is the uncertainty

of the devices lifetime.

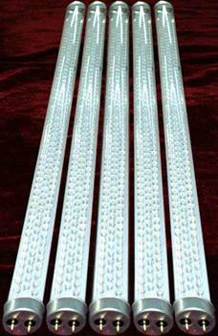

Some 40 watt fluorescent lamp replacements, such as shown to the right are examples of very poor economics. A $3 40w fluorescent lamp is pretty cheap. A LED replacement lamp would have to last a lot longer and produce as much light with much less power to be viable. LED lighting for street lights is even more of a challenge. Although some people like the broad spectrum of LED lights for street illumination, other long life and efficient light sources are already pretty economic. The very common sodium vapor and mercury vapor lamps are not bad. An LED replacement would need to be far superior before they are accepted. They especially need to have very long lifetimes. |

If we ignore the gradual fading of the intensity

Cost per lumen still is expensive

Cost savings much be more than just lumens per watt. The devices must also last much longer than standarad lights.

Heat dissipation factors will force manufacturers to spend more money on the fixture than other light sources.

A replacement for a standard 40 watt fluorescent lamp will still not be economically viable for many more years. The lifetime of the LEDs must be extended well beyond 3 to 5 years if they are ever to become competitive.

Perhaps a means to compensate for loss of effieicy could be devised. Maybe more power is routed to the part to make up for the difference.

I have never see a fluorescent lamp for street lighting

Sodium vapor and mercury vapor have dominated that applcaiton for decades.

LED Lighting Economics

February 19, 2010

Although light emitting diodes (LEDs) have been around for at least 3 decades, they have really been in the news a lot lately. For the first time, these devices are producing much more light than other traditional light sources, using less power. The table below lists the typical electrical power to light conversion factor for various light sources. Note that the latest xyz from Cree claims to surpass the fluorescent lamp with a xyz lumens per watt figure. However, when reading the fine print, this figure is only for pulsed conditions and not continuous operation. Still, if these superb watts per lumen improvements continue, we should start seeing more and more LEDs in home and office lighting fixtures.

When jumping from incandescent lamps to compact fluorescent lamps, the power savings are huge and easy to calculate. However, when moving from fluorescent lamps, such as those often used in office buildings, to LED lighting, the savings are not that clear. The main reason, is the uncertainty of the devices lifetime. Some 40 watt fluorescent lamp replacements, such as shown below are examples of very poor economics. A $3 40w fluorescent lamp is pretty cheap. A LED replacement lamp would have to last a lot longer and produce as much light with much less power to be viable. LED lighting for street lights is even more of a challenge. Although some people like the broad spectrum of LED lights for street illumination, other long life and efficient light sources are already pretty economic.

The very common sodium vapor and mercury vapor lamps are not bad. An LED replacement would need to be far superior before they are accepted. They especially need to have very long lifetimes.

If we ignore the gradual fading of the intensity

Cost per lumen still is expensive

Cost savings much be more than just lumens per watt. The devices must also last much longer than standarad lights.

Heat dissipation factors will force manufacturers to spend more money on the fixture than other light sources.

A replacement for a standard 40 watt fluorescent lamp will still not be economically viable for many more years. The lifetime of the LEDs must be extended well beyond 3 to 5 years if they are ever to become competitive.

Perhaps a means to compensate for loss of effieicy could be devised. Maybe more power is routed to the part to make up for the difference.

I have never see a fluorescent lamp for street lighting

Sodium vapor and mercury vapor have dominated that applcaiton for decades.

LED Street Lights

LPS lamps are the most efficient electrically-powered light source when measured for photopic lighting conditionsup to 200 lm/W,[6

Another unique property of low pressure sodium lamps is that, unlike other lamp types, they do not decline in lumen output with age. As an example, mercury vapor HID lamps become very dull towards the end of their lives, to the point of being ineffective, while continuing to consume full rated electrical use. LPS lamps, however, do increase energy usage slightly (about 10%) towards their end of life, which is generally around 18,000 hours for modern lamps.

High pressure sodium lamps are quite efficientabout 100 lm/Wwhen measured for photopic lighting conditions

The efficacy of fluorescent tubes ranges from about 16 lumens per watt for a 4 watt tube with an ordinary ballast to as high as about 100 lumens per watt for a 32 watt tube with modern electronic ballast, commonly averaging 50 to 67 lm/W overall. Most compact fluorescents above 13 watts with integral electronic ballasts achieve about 60 lm/W. Lamps are rated by lumens after 100 hours of operation.[12] For a given fluorescent tube, a high-frequency electronic ballast gives about 10% efficacy improvement over an inductive ballast. It is necessary to include the ballast loss when evaluating the efficacy of a fluorescent lamp system; this can be about 25% of the lamp power with magnetic ballasts, and around 10% with electronic ballasts.

About 24% of the energy used by metal halide lamps produces light (65115 lm/W[1]), making them generally more efficient than fluorescent lamps, and substantially more efficient than incandescent bulbs.

The following table lists luminous efficacy of a source and efficiency for various light sources:

|

Category |

Type |

Overall |

Overall |

|

Combustion |

0.3 [10] |

0.04% |

|

|

|

12 [11] |

0.150.3% |

|

|

100200 W tungsten incandescent (220 V) |

2.02.2% |

||

|

|

100200500 W tungsten glass halogen (220 V) |

2.42.62.9% |

|

|

|

540100 W tungsten incandescent (120 V) |

0.71.82.6% |

|

|

|

2.6 W tungsten glass halogen (5.2 V) |

19.2 [16] |

2.8% |

|

|

tungsten quartz halogen (1224 V) |

24 |

3.5% |

|

|

photographic and projection lamps |

35 [17] |

5.1% |

|

white LED (raw, without power supply) |

0.6622.0% |

||

|

|

4.1 W LED screw base lamp (120 V) |

58.582.9 [22] |

8.612.1% |

|

|

6.9 W LED screw base lamp (120 V) |

55.181.9 [22] |

8.112.0% |

|

|

7 W LED PAR20 (120 V) |

28.6 [23] |

4.2% |

|

|

8.7 W LED screw base lamp (120 V) |

10.113.6% |

|

|

4.47.3% |

|||

|

|

5055 [25] |

7.38.0% |

|

|

T12 tube with magnetic ballast |

60 [27] |

9% |

|

|

|

932 W compact fluorescent |

811.45% [30] |

|

|

|

T8 tube with electronic ballast |

80100 [27] |

1215% |

|

|

T5 tube |

1015.63% |

|

|

1400 W sulfur lamp |

100 [33] |

15% |

|

|

|

65115 [34] |

9.517% |

|

|

|

1222% |

||

|

|

1529% |

||

|

Ideal sources |

Truncated 5800 K blackbody [8] |

251[citation needed] |

37% |

|

|

Green light at 555 nm (maximum possible LER) |

683.002 [9] |

100% |

Sources that depend on thermal emission from a solid filament, such as incandescent light bulbs, tend to have low overall efficacy

New kid on the block is the electrodeless fluorsecent lamp.

Fluorescent lamps are not well suited for cold temperature operation.