Testing

LED Light Intensity

By: Dave Johnson |

|

|

|

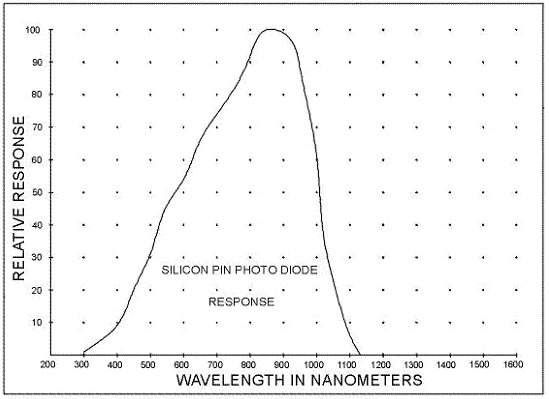

The human eye is not a good

instrument for measuring how bright a light is. Our eyes tend to be

logarithmic. When making a comparison between two lights, unless one

light is considerably brighter than the other, you will not know which is

really brighter. You need a linear device to make such a

measurement. You donít have to

spend a lot of money to make good intensity measurements. A fairly

accurate device is the bare silicon photodiode. As the cart below

illustrates, a silicon photodiode has a broad light response, covering

invisible ultraviolet, through the entire visible spectrum, into the

invisible near infrared band. These parts act as small solar cells.

The DC current generated by them is directly proportional to the

|

| light

intensity. By positioning one of these things directly in front of a

light source, you can accurately measure how bright one part is with

respect to another. This method does not take into account the

emission pattern of the part, or its color. It only tells you what

the relative intensity is. It works best when you are comparing one

device with another of the same color, package size and emission pattern.

By placing the photodiode very close to the LED under test, the emission

pattern has less impact on the intensity reading. Most of the light

emitted, strikes the photodiode. |

|

| The most popular LED package

is the 5mm diameter T 1 ĺ part. The position of the LED chip within

the epoxy package controls the light pattern that emerges. If the

chip is mounted back from the lens, the pattern is narrow.

Conversely, if the chip is moved closer to the lens, the pattern is

broader. The standard LED specification for the emission angle is

the angle from the center of the part to the half power point. This

is a half angle. Some LED data

sheets double this angle for a full angle. So, a device with a 10

degree half angle may be listed as having an emission pattern of 20

degrees. Keep in mind that when viewed from some distance away, a

LED with a narrow emission pattern will appear brighter than one with a

broader pattern, even if the broader pattern part emits more light power. |

|

|

|

|

| LED with a

Narrow Pattern |

LED with a

Broad Pattern |

|

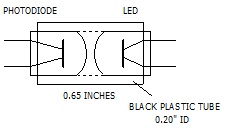

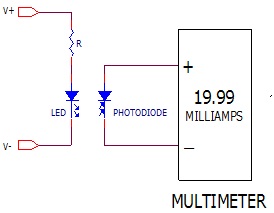

| When testing T 1 ĺ

type LEDs, I reach for my photodiode test tool. As illustrated, this

assembly is just a photodiode slipped into a black plastic tube about 0.65

inches long. The LED under test slides into the other end of the tube.

The black plastic prevents most ambient light from reaching the photodiode.

I then connect the photodiode to my multimeter, set for the DC current mode and

a 20ma range. The current reading I get on the multimeter is then the

light intensity. |

|

|

|

The photodiode I use most

often use is the PDB-C142 from Advanced Photonix Inc. This device

costs about $3.00 and is available from

www.digikey.com. Other possible devices are shown below.

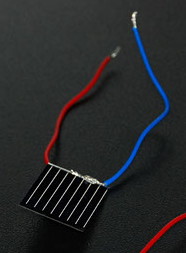

In a pinch, you can even use a small solar cell. When using a bare

solar cell try to make your measurements under low ambient light levels.

Otherwise you will get a false reading. When picking a photodiode,

be sure to only use those with a clear window. Donít use photodiodes

with a purple tint. These contain a special daylight blocking filter

which filters out most visible light. Also, be sure to only use a

photodiode. Phototransistors are often listed as light detectors but

they are very logarithmic parts and will not give you a good linear

response. |

|

|

|

|

|

|

| Advanced

Photonix PDB-C142 |

BPW34

|

BPW46 |

PDVC158 |

BPV10 |

|

|

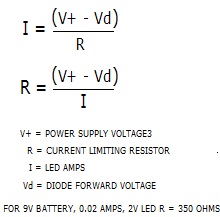

When testing LEDs, the best

way to drive them is with a constant current. Twenty milliamps seems

to be the industry standard for most LEDs. You can approximate a

constant current by inserting a resistor in series with the LED and a DC

power supply. You can use the formula below for picking the resistor

value. Red LEDs have a forward voltage between 1.5v and 2.0v.

Orange and yellow require about 2 volts. Green parts need about 2.5v

to 2.8v. Blue and white LEDs need something between 3.2v and 3.6v.

Nearly all ultraviolet LEDs need about 3.6v while nearly all infrared LEDs

need about 1.5v. |

|

| Small Solar

Cell |

|

| Over the years I have

been very disappointed by how poor some white LEDs used in many solar path

lights and flash lights are. They may look bright but by using this simple

test tool, the intensity measurements tell a different story. Some white

LEDs made by Cree are two and sometimes three times brighter at the same current

level. If you are not satisfied with a particular path lightís output, you

can make a big difference just by replacing the LED with a better part from

Cree. Also, if you are satisfied with the path lightís intensity but not

the time it operates, you can replace the lightís LED with a Cree part and

extend the operating time by 2X or 3X by increasing the internal resistor which

controls the LED current and thus lowering the drive current. Flashlights

too can benefit by swapping out the LEDs for better parts. I have also

used this simple setup to monitor how some parts age over time. Some cheap

white LEDs offered on eBay fade to a half intensity level in just a few weeks of

use. |

|

|