|

|

|

|

|

|

|

|

|

Corona Monitor |

|

Wily was just about to have some

lunch when his phone rang. It was from a local medical equipment company.

They made kidney dialysis machines. They also made lots of the non-reusable blood

filters, which were used on their machines. The filters were rather complex

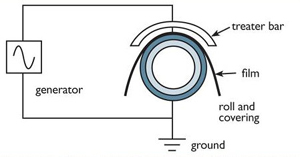

canisters of plastic sheets, all glued together. To enhance the glue adhesion, the

company ran the plastic sheets through a special machine, which bombarded the material

with a high voltage 40KV 20KHz discharge. This “corona discharge” broke up the

plastic bonds on the surface, allowing the glue to stick. |

| The company had been using their

corona machine for several years without too many problems. However, on occasion,

the machine might hiccup for a few seconds. The glitch lasted long enough to allow

sections of the filter plastic sheets to pass through the system without being properly

treated. One or more blood filter assemblies would then be completed and only later

rejected due to leaks in the filter, caused by the glitch. The company wanted a more

robust system, which would monitor the corona and stop the take-up rollers for the plastic

sheets, whenever a glitch occurred. The operator could then correct the problem,

pull the plastic sheets back a few feet, and start up again. Could Wily come up with

something? |

|

|

| Dialysis

Machine |

Dialysis Filter |

| |

|

|

|

| Corona Treatment System |

Corona Light |

| |

|

|

|

| The

company had been using their corona machine for several years without too many problems.

However, on occasion, the machine might hiccup for a few seconds. The glitch lasted

long enough to allow sections of the filter plastic sheets to pass through the system

without being properly treated. One or more blood filter assemblies would then be

completed and only later rejected due to leaks in the filter, caused by the glitch. The

company wanted a more robust system, which would monitor the corona and stop the take-up

rollers for the plastic sheets, whenever a glitch occurred. The operator could then

correct the problem, pull the plastic sheets back a few feet, and start up again. Could

Wily come up with something? |

|

The medical company explained that they

wanted Wily to design for them a corona detection system, which would tie into their

computer. Their computer controlled the whole corona treatment process. They already

had an audible alarm generator and a big emergency stop button. That button also

acted as a rest button, when pulled. All they needed from Wily was a logic signal

that would swing low when no corona was detected. |

|

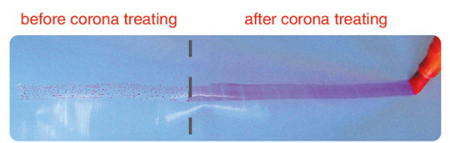

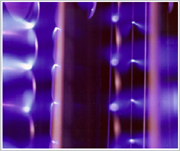

Wily scheduled a visit to

the company’s production line the next day. He took with him some light

measurement equipment and a camera, to capture some images of the corona machine in

operation. When Wily was shown the system in operation he immediately noticed

that the corona discharge produced a very bright violet light. The light was a

mixture of visible blue and invisible ultraviolet light. He took some quick

light output measurements with the corona on and off, using a bare silicon

photodiode, connected to a multimeter. Based on those quick tests, Wily

decided that detecting the visible and the invisible ultraviolet light produced by

the corona would be the way to go. Wily collected some physical data from the corona

treatment machine and then went back to his lab and started the designing process. |

| In addition to light, Wily

was told that the corona discharge produced a large amount of broadband radio

frequency noise. This electrical noise could interfere with any sensitive electronic

circuit placed nearby. In fact, to prevent RF interference problems, the

medical company had placed all the control corona system electronics inside large

vertical metal racks, which were positioned on either side of the corona treatment

station. The steel racks shielded the electronics inside from the electrical noise.

Wily decided that the light sensor and associated electronics should also be housed

inside one of those equipment racks, which was about 6 feet away from the corona.

He saw a good spot for his corona monitoring box, just above one of the system’s DC

power supplies, on an empty rack shelf. |

| 19 Inch

Equipment Racks |

|

|

To collect the light from the corona, Wily

decided to use an optical fiber bundle about 10 feet long and about 0.40 inches in

diameter. The 0.2 inch bundle inside was made of many tiny strands of optical fibers. The

bundle assembly was held inside a plastic jacket. Wily carefully removed the jacket

from a section of the bundle. He then slid it into the center barrel of a coax type

connector and glued the bundle in place with an optical grade epoxy. That connector

would later be used to shine the collected light onto a photodiode, to measure the light

intensity. The connector would make it easier to service the system, if needed.

On the light collection end, he removed a small section of the plastic jacket and covered

the bundle with more optical grade epoxy. Once the epoxy cured, using various

sandpaper grits, he then polished both ends of the bundle, to a smooth finish. This

treatment improved the light collection and coupling. |

|

The medical company fabricated a custom

plastic holder for the fiber bundle and installed it onto part of the corona bar.

The bundle was positioned so it pointed down toward the corona to within a half inch of

the discharge. The fiber bundle would then collect the light emitted by the discharge and

send it to the other end of the bundle. |

|

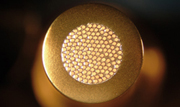

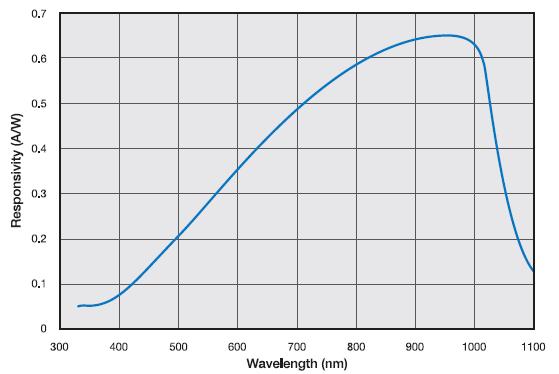

Wily carefully positioned the photodiode

inside the corona monitor’s metal box so when the fiber bundle connector was installed

onto the box’s matching connector receptacle the fiber bundle end lined up with the center

of a bare silicon PIN photodiode. Wily chose a photodiode about 0.5cm x 0.5cm in

size. As shown below, the photodiode had a response curve, which included

ultraviolet light. |

|

|

| Corona Light |

Optical Fiber Bundle |

|

|

|

Silicon PIN Photodiode

|

Photodiode Response

Curve

|

|

|

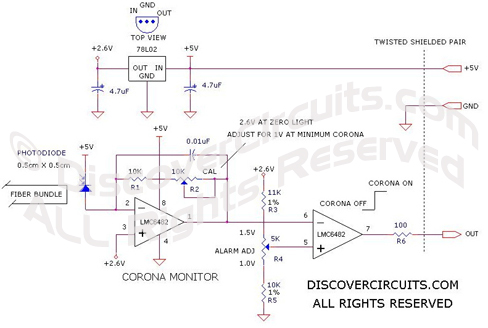

Wily’s light corona monitoring and alarm

circuit was pretty simple. The circuit was powered by +5v and had an on-board

voltage regulator as a reference voltage. The current from a reversed biased

photodiode was converted into a voltage using an op Amp circuit. That output voltage

was fed to a voltage comparator circuit. Wily included an adjustment in the current

to voltage converter, so he could calibrate the circuit, once it was installed on the

corona treatment machine. He would set the gain of the circuit so it would produce a

one volt output signal for a typical corona discharge. The comparator’s threshold

voltage could also be adjusted, so the device would change state when the corona intensity

dropped by about 20%. The alarm output of the monitoring circuit was connected to

the company’s computer through a three pin connector. That alarm signal controlled

the treatment process. When the computer sensed the corona alarm signal, it would

shut down the system. A human operator would then back up the plastic film a few

feet and rethread it into the take-up rollers. Finally, he would press the reset

button, which told the computer to start up the film treating process again.

|

| |

|

|

|

|