|

|

|

|

|

|

|

|

| |

|

Super Hot Ferrite Transformer

I got a desperate call from an

ultrasound cleaning machine company. For many years they had successfully been

making 350w units, which ran off 120vac and drove 6 big 40KHz piezoelectric transducers.

But when the manufacture of the big ferrite driver transformers they used in their driver

board went out of business, they were forced to find a replacement from another company.

But, they could not seem to get a replacement transformer to work properly. Transformers

from their new supplier would work for a while but soon got so hot, they smoked. What were

they doing wrong? |

|

|

|

| Ultrasonic Cleaning

Machine |

Cleaning Machine Driver

Board |

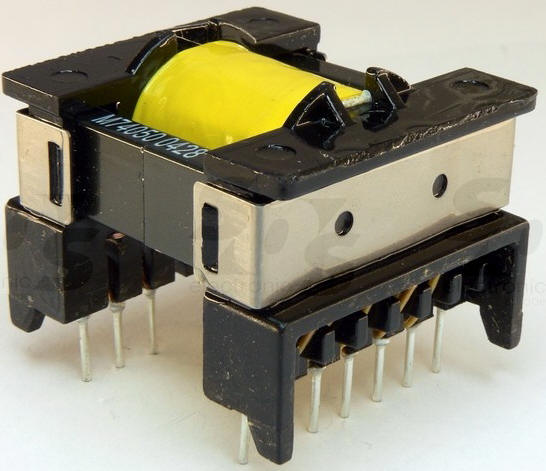

Ferrite Transformer |

|

|

I asked the company to send me one of the new transformers and if possible,

at least one transformer from one of their old machines. |

|

When I received the units, I noted that there were no markings on either

device. The old and new transformers looked very much alike. Both had the same

size ferrite E cores and used the same plastic bobbin with identical solder pins.

However, the windings on the new part seem to be taking up a bit more volume around the

core than the older device. This could be a clue, so I made a mental note. |

|

I measured the inductances of all the windings. The inductances of both old

and new transformers were about the same at both the primary and secondary windings.

Since both primary and secondary inductances were about the same, it meant that the

primary and secondary turns ratios were also about the same. No help there. |

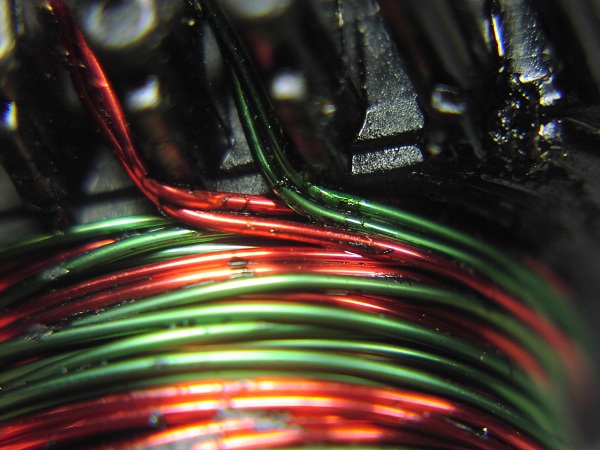

| A careful

inspection of the transformer wires on the old and new devices produced valuable clue. The

old transformer used 8 magnet wires for the windings, while the new device used just two

wires of a larger gauge. Winding the transformer with multiple wires can

dramatically reduce the complex impedance of the windings due to skin effect. A

single wire, even a larger gauge wire, would have much more resistance than multiple

insulated wires in parallel. The skin effect would certainly be larger in the two

wire windings when compared with the 8 wire windings. But, would it be so large that

it would cause the thing to smoke? It would certainly be a contributing factor but I

thought something else was the major cause for the excessive heating. |

|

|

| Two-Wire Transformer

Windings |

Eight-Wire Transformer

Windings |

|

|

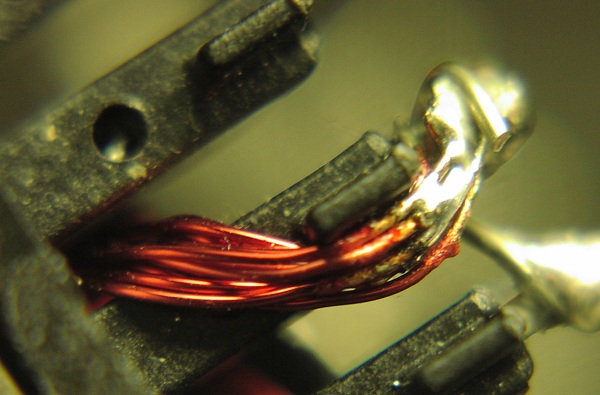

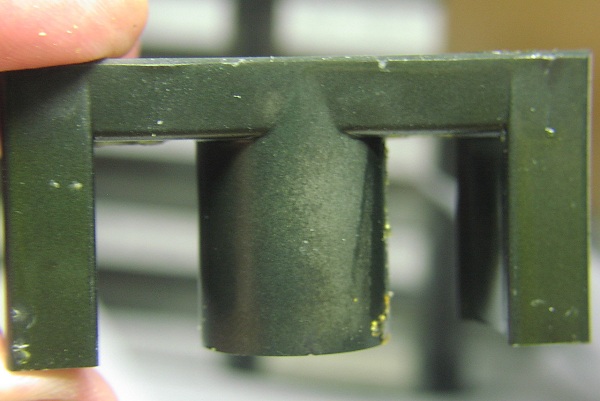

| Ferrite E-Core |

Excessive

Heat Melted Bobbin |

|

|

Judging by the physical size of the windings on the new part, it appeared

that the manufacturer used more copper in his part than used in the older part. I

had a theory. I speculated that the new manufacture tried to match the inductances

and core size. But, he might have used a cheaper core material, with a lower

permeability. A lower permeability would mean the transformer would need more turns

to achieve the same inductance. I tested this theory by winding ten turns of wire

around the core of both the old and new transformers and compared the inductance of the

two. I determined that the new core did indeed have a lower permeability. The

ratio was nearly 4 to one. Bingo! |

|

It was now all making sense. Not having clear specs to go by, the new

transformer manufacturer designed his part to match the inductances, size and pinouts of

the old part. But, he used a core with a lower permeability which forced him to use

more turns in each winding. He also used only two wires in parallel for each winding

instead of using 8 wires. This too lowered the cost of the part but made the

transformer much less efficient. I guessed that the combination caused the poor

transformer to dissipate 4 times more heat than the old part. No wonder the part was

smoking. A quick phone call to the transformer company nailed down the proper core

material as well as the number and gauge wire size for all the windings. Transformer

samples were quickly shipped to the cleaning machine company who later reported to me that

the new new part worked perfectly. |

| The lesson

here is that good transformer specifications are critical in products like the ultrasonic

cleaning machine and those specs need to be carefully defined in engineering terms, not

just model XYZ from ABC company. Whenever, possible, I like to include some of those

specs right on the circuit schematic. Those notes could be all that were needed to

insure proper transformer design, in the event written transformer specs were lost. |

|

|

|