|

NiMH

Battery State of Charge

Monitor

By: Dave Johnson |

|

Problem:

For the last 6 years or so, I have been using rechargeable NiMH

batteries for my MP3

players, my portable CD players, batteries for my digital cameras and AM/FM radios.

Rechargeable batteries make sense for devices which are used frequently. A good

battery can be recharged 100s of times. The ability to recharge a battery over and

over can really save a lot of money, not to mention less material sent to the dump.

But, lately I have been quite frustrated and angry at some of the rechargeable NiMH

cells I have purchased. |

|

| The quality of these

devices seems to be getting worse and worse. The last round was a packet of 8

AA cells which I paid about $20 for. The batteries were made in China with

the American name “Duracell.” They were supposed to be rated at about 2.5

Amp-hours but although they were purchased new, they behaved like they were many

years old. With a good set of batteries installed, I can usually get to

play 6 or 7 CDs on my portable player before the pack of two AA cells would run

out of juice. The Duracell batteries died after playing only 2 CDs.

It was not just one bad cell in the bunch either. All the batteries had

the same low energy capacity. In contrast, I have some batteries which are

at least 5 years old and they are still going strong. How do you know when

you have a stinker in the bunch? |

| Typical Testing

Methods: The conventional way to measure the quality of a rechargeable

battery takes time. You first have to fully charge the device. Then,

you discharge it, usually at a constant current, and time how long the battery

can maintain that current before its voltage drops below a certain critical

cut-off point. In an AA battery, with a 2500 milliamp hour capacity, that

test could take a while, often days. In theory, with perfect battery, a 2.5

Amp-hour battery could support a 2.5 Amp load for an hour. But in

practice, the actual time would be much shorter. Internal resistance of

the battery prevents the efficient extraction of that energy. The 2.5

Amp-hour is usually defined with a much lower current, often down to 10

milliamps or so. At such a low current, it would take 250 hours or over 11

days complete a test. That kind of test would be impractical. It may

be possible to apply perhaps a 1 Amp load to the battery and compare how long

the battery supports that current to a known good battery. An hour long

test would certainly be better than one that takes over a week but it is still

way too long if you are trying to sort out some bad apples in a box of

batteries. I’d like to see if there might be a quicker way. |

| Proposed Faster

Testing Method: For many years I

thought that a pulsed dv/dI technique might be used to quickly determine the

health of a battery. This test involves drawing a heavy current pulse from

the battery and measuring the voltage change that results. This technique

in fact measures the internal resistance of the battery. A healthy

battery, when fully charged, should display a fairly low internal resistance.

As the battery ages, perhaps over the course of years of service, the internal

resistance should increase. But, the internal resistance will also

increase as the battery is discharged. So, this pulsed technique may be

used to weed out some fully charged but bad batteries and may also be used to

determine how much juice is left in the battery as it is discharged. The

first objective in this project is to come up with some statistics, so a typical

curve could be plotted showing the relationships between Amp-hour capacity, the

percentage of charge and the internal resistance. |

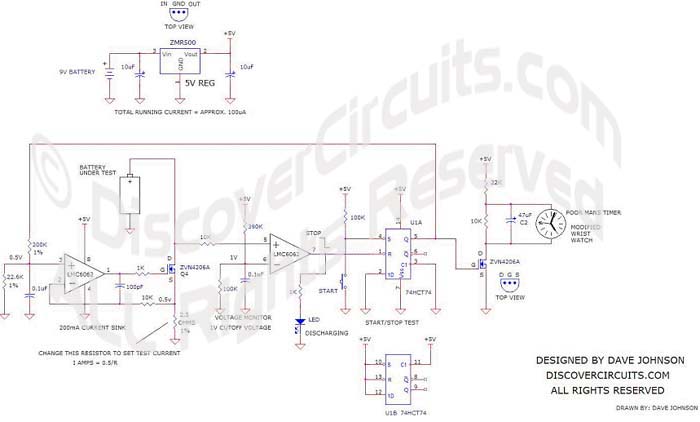

| Overnight Battery

Capacity Test: The circuit below

should work for testing some batteries over an 8 hour or so period. The

circuit draws a constant 200ma of current from a fully charged battery and times

how long the battery can support that current before its voltage drops below

1.0v. I’ll use a cheap clock or watch, set up as an elapsed timer. I

expect that a good cell will run for perhaps 8 to 10 hours. I should be

able to test about two cells per day with this circuit. |

|

|

|

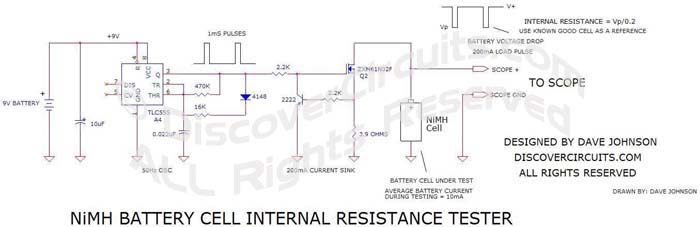

Delta V Battery

Resistance Test Circuit: The first objective for this round of

experiments is to see how consistent the internal resistance of some batteries

is, once fully charged. I think I will first try using the circuit shown

below. This simple circuit will pulse the battery with 1ms 200ma pulses. I

will use my scope to measure the voltage drop in battery voltage with each

pulse. I’ll first charge up a bunch of batteries then measure the

resistance with this circuit. I then will try to develop a relationship

between the measured internal resistance and the measure Amp-hour capacity of

the cell. I would expect to see a higher resistance for those cells which

have a lower Amp-hour capacity. After those tests, the last step in the

process would be to discharge batteries to some repeatable point, and try and

come up with a relationship between state of charge and internal resistance.

That might take a bit of head scratching. I will share with you my test

results. |

|

|

|

|

|

|